|

Grearth Filter Plate Co., Ltd

|

Replaceable membrane filter plate, low contamination and durable

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

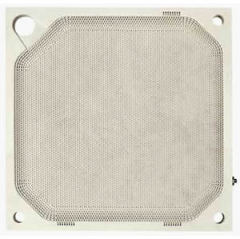

Replaceable membrane filter plate features easy replacement, low maintenance cost, longest life span and reuse.

Replaceable membrane filter plate can be roughly separated into three parts - core plate and two membranes. This special construction gives its capability of replaceable membrane apart from the main advantages ofwelded membrane filter plate. Once the membrane has been damaged due to aging or external forces, just replace the membrane without using a new membrane plate. What is more, the membrane replacement can occur in the filter press.

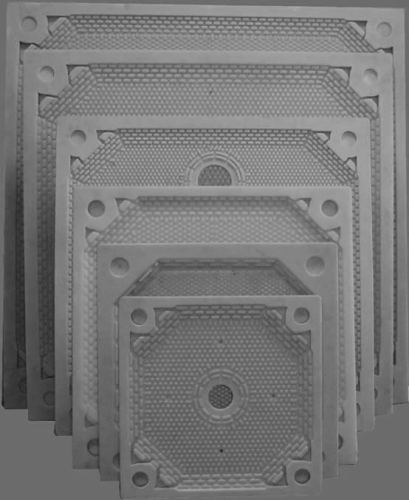

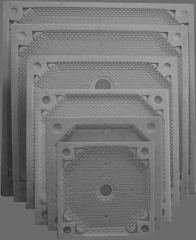

Diverse sizes of replaceable filter plate are manufactured. Special sizes or shapes are also customized.

Rubber membrane filter plate features good flexibility and is compatible with most types of slurry.

High pressure membrane filter plate suitable for extremely high working pressure

Replaceable membrane filter plate uses metal ring to lock the membranes and core plates. It is widely used for rubber is quite compatible with a lot of kinds of slurry.

Note: Replaceable membrane plates must be cooperated with chamber filter plate.

Features

Easy membrane replacement even after a couple years of operation

Core body plate and membrane can be fabricated in different materials.

Standard thickness of the membrane is rated at 3 to 4 mm.

Follow-up maintenance cost will be much lower.

Standard working pressure ranges from 7 bar to 16 bar.

Working temperature is up to 120°C.

Easy membrane replacement even after a couple years of operation

Core body plate and membrane can be fabricated in different materials.

Standard thickness of the membrane is rated at 3 to 4 mm.

Follow-up maintenance cost will be much lower.

Standard working pressure ranges from 7 bar to 16 bar.

Working temperature is up to 120°C.

Materials

Various materials are used, such as polypropylene, thermoplastic elastomer (TPE), synthetic rubbers such as EPDM, NBR, and PVDF. The individual part of replaceable membrane filter plate can be made of different materials to meet with diverse applications.

Various materials are used, such as polypropylene, thermoplastic elastomer (TPE), synthetic rubbers such as EPDM, NBR, and PVDF. The individual part of replaceable membrane filter plate can be made of different materials to meet with diverse applications.

Feed position

Standard: center feed, corner feed, head feed and external feed. Other special feed positions are manufactured for particular purposes.

Standard: center feed, corner feed, head feed and external feed. Other special feed positions are manufactured for particular purposes.

Standard size

470, 8000, 1000, 1200, 1300, 1500, 2000mm in square shapes. For odd shapes or larger sizes are available for special orders.

470, 8000, 1000, 1200, 1300, 1500, 2000mm in square shapes. For odd shapes or larger sizes are available for special orders.

Diverse sizes of replaceable filter plate are manufactured. Special sizes or shapes are also customized.

Rubber membrane filter plate features good flexibility and is compatible with most types of slurry.

High pressure membrane filter plate suitable for extremely high working pressure

Replaceable membrane filter plate uses metal ring to lock the membranes and core plates. It is widely used for rubber is quite compatible with a lot of kinds of slurry.

Related Search

Membrane Filter

Membrane Filter Cartridge

Membrane Disc Filter

Ptfe Membrane Filter

Membrane Filter Press

Low Alloy Plate

More>>