|

Grearth Filter Plate Co., Ltd

|

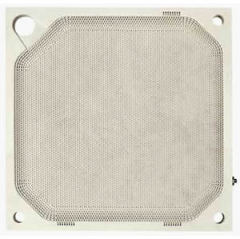

Ceramic filter with unique porous structure used in diverse fields

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Ceramic filter plate is an alternative of separation solid and liquid for its high mechanical strength, high working temperature and less contaminatio

Ceramic filter plate is an alternative method of solid and liquid separation. Porous ceramic filter tends to replace conventional filter plates for its extremely high working temperature, chemical inertness and excellent resistant to almost types of slurry.

Ceramic filter is used to remove solid particulate from liquid and gas in chemical process, petrochemical, food and beverage, pharmaceutical industries, paper making and ore concentrate dewatering of copper, lead, zinc, iron, silver, sulfur, gold for its unique porous structure.

Features

- High mechanical strength

- Excellent resistance against abrasion and corrosive against acid and alkali.

- Pore size is uniform and precise.

- Chemical inertness makes it suitable for a great number of applications.

- Extremely low moisture of filter cake is particularly.

- Filtrate treated by ceramic filter plate is clear enough to be used as industrial circulation water.

- Porous ceramic plate can be cleaned by organic solutions and reused for many times.

- Non-destructive permeability test is performed to verify pore size and filter ration.

Product description

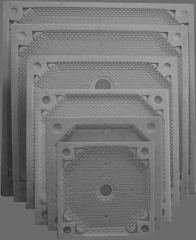

Open porosity: 40% - 90%

Pore size: 0.25 to 90 microns

Dimensions: 1/12 to 8/12 square meter

Open porosity: 40% - 90%

Pore size: 0.25 to 90 microns

Dimensions: 1/12 to 8/12 square meter

Materials

Aluminum oxide is the most popular raw material of ceramic plate. its maximum operation temperature can reach 1400 ℉.

Silicon carbide is the premier choice for harsh applications, for its maximum working temperature can be as high as 1800 ℉.

Aluminum oxide is the most popular raw material of ceramic plate. its maximum operation temperature can reach 1400 ℉.

Silicon carbide is the premier choice for harsh applications, for its maximum working temperature can be as high as 1800 ℉.

| Ceramic filter plate | Ceramic filter plates have been cleaned by organic solvents and can be reused. |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Porous Ceramic Balls

Ceramic Structure Packing

Unique Ceramic Tile

Ceramic Filter

Daily Used Ceramic

Used Oil Filter

More>>